GeoWood Engineered SPC Flooring Installation

VIEW OR DOWNLOAD:

Pro GeoWood Guide

VIEW OR DOWNLOAD:

Pro GeoWood Installation Guide

Floating Click-Lock Pre-Installation

Floating Click-Lock Pre-Installation

Before you begin installation, remember to P.A.C.E. yourself with the checklist below.

Note: Flooring not used for its intended purpose will not be covered under warranty.

- Upon ordering of GeoWood floor materials consider adding an additional 5% to allow for cutting waste and grading allowance.

- CALI flooring is manufactured in accordance with accepted industry standards, which permit manufacturing, grading and natural deficiencies not to exceed 5%. If more than 5% of the material is unusable, do not install the flooring. Immediately contact the distributor/retailer from which the flooring was purchased. No claim will be accepted for materials with visible defects once they are installed. Installation of any material serves as acceptance of the material delivered.

- Installer/Owner assumes all responsibility to inspect all flooring before installation. Planks deemed unacceptable in appearance can be placed in closets, near walls or simply not be used. Pieces with glaring defects that can be seen from a standing position should be cut off or not be used as use constitutes acceptance.

- It is the responsibility of the installer/homeowner to determine if the job site conditions, environmental conditions and sub-floor are acceptable for the installation of CALI GeoWood flooring. Prior to installation, the installer/owner must determine that the jobsite meets or exceeds all applicable National Wood Flooring Association Installation Guidelines. CALI does NOT warrant against failure resulting from or connected with subfloor, job site damage, or environmental deficiencies after installation. CALI makes no warranty or guarantee of the quality of the chosen installer’s work or of a particular installation performed by him or her. CALI disclaims all liability for any errors or improprieties in the installation of its products by an installer.

- Floor noise is normal and will vary from one installation type to the next. Occasional noise is due to structural movement and may relate to sub-floor type, flatness, deflection, and/or related to the fasteners, changes in environmental conditions, relative humidity and the amount of topside pressure applied to the flooring. For these reasons floor noise is not considered a product or manufacturer defect.

- During installation, it is the installer’s responsibility to document all jobsite conditions and measurements including the installation date, site relative humidity, temperature, and subfloor moisture content. This information must be retained by the installer and left with the property owner as a permanent record. For a complete list of points to address prior to installation, refer to the NWFA Jobsite checklist.

- Do not install flooring under permanent or fixed cabinetry.

- Never nail or screw anything through a FLOATED floor.

Transport, Storage, Acclimation

- Transport and store cartons in lay down, flat position.

- Stack boxes no more than 8 cartons (4ft) high. Keep away from direct sunlight.

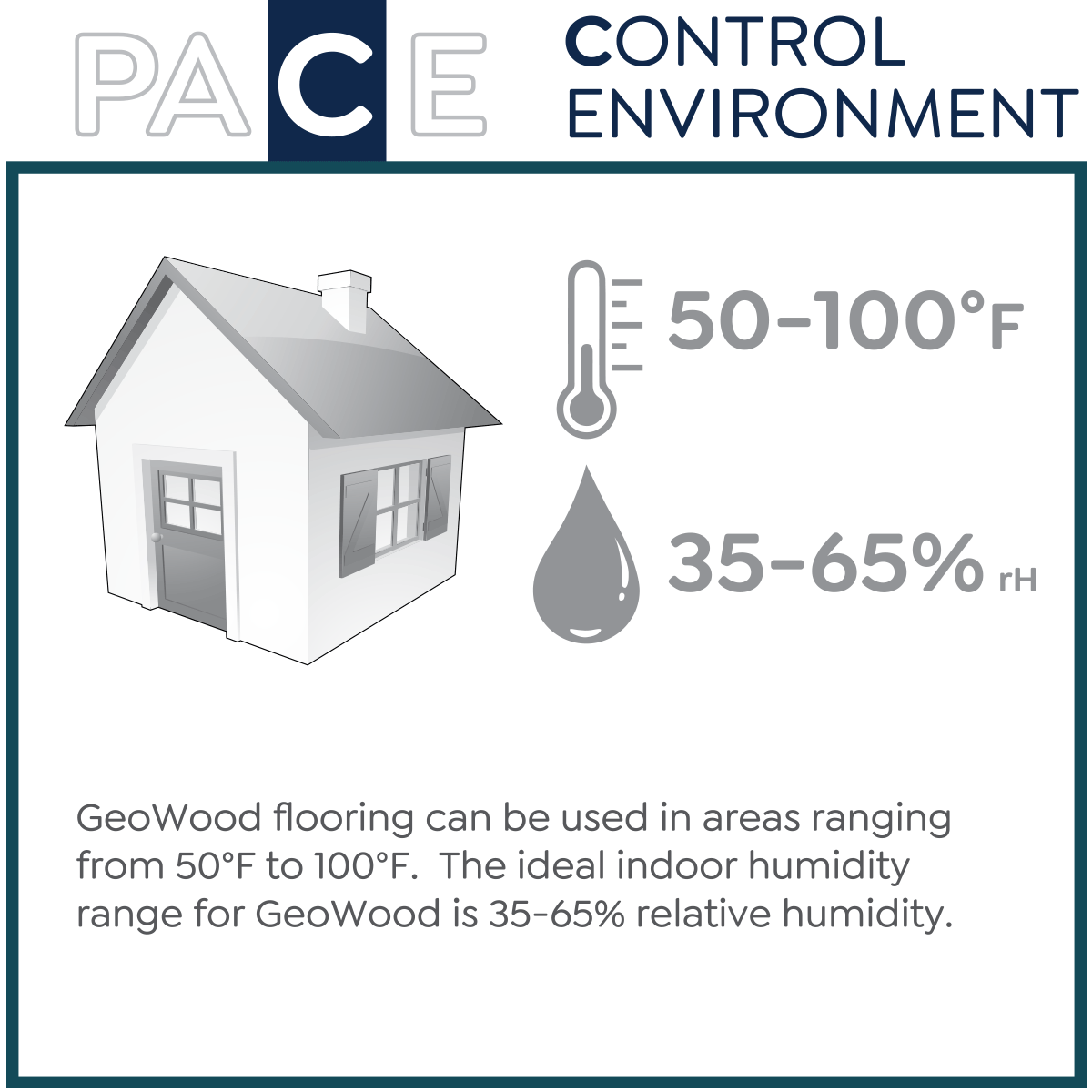

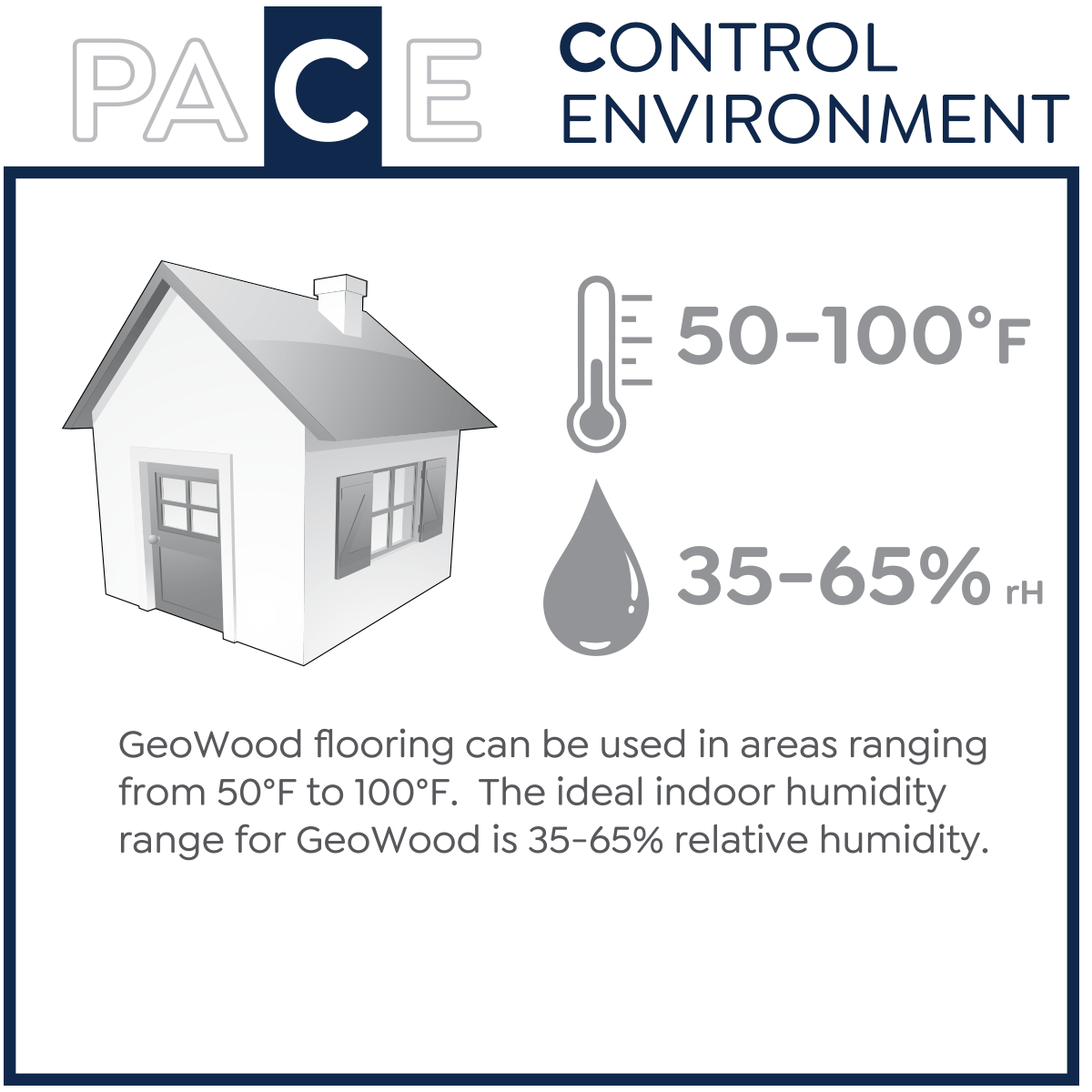

- Room temperature and relative humidity must be consistent with year-round living conditions for at least 5 days prior to installation.

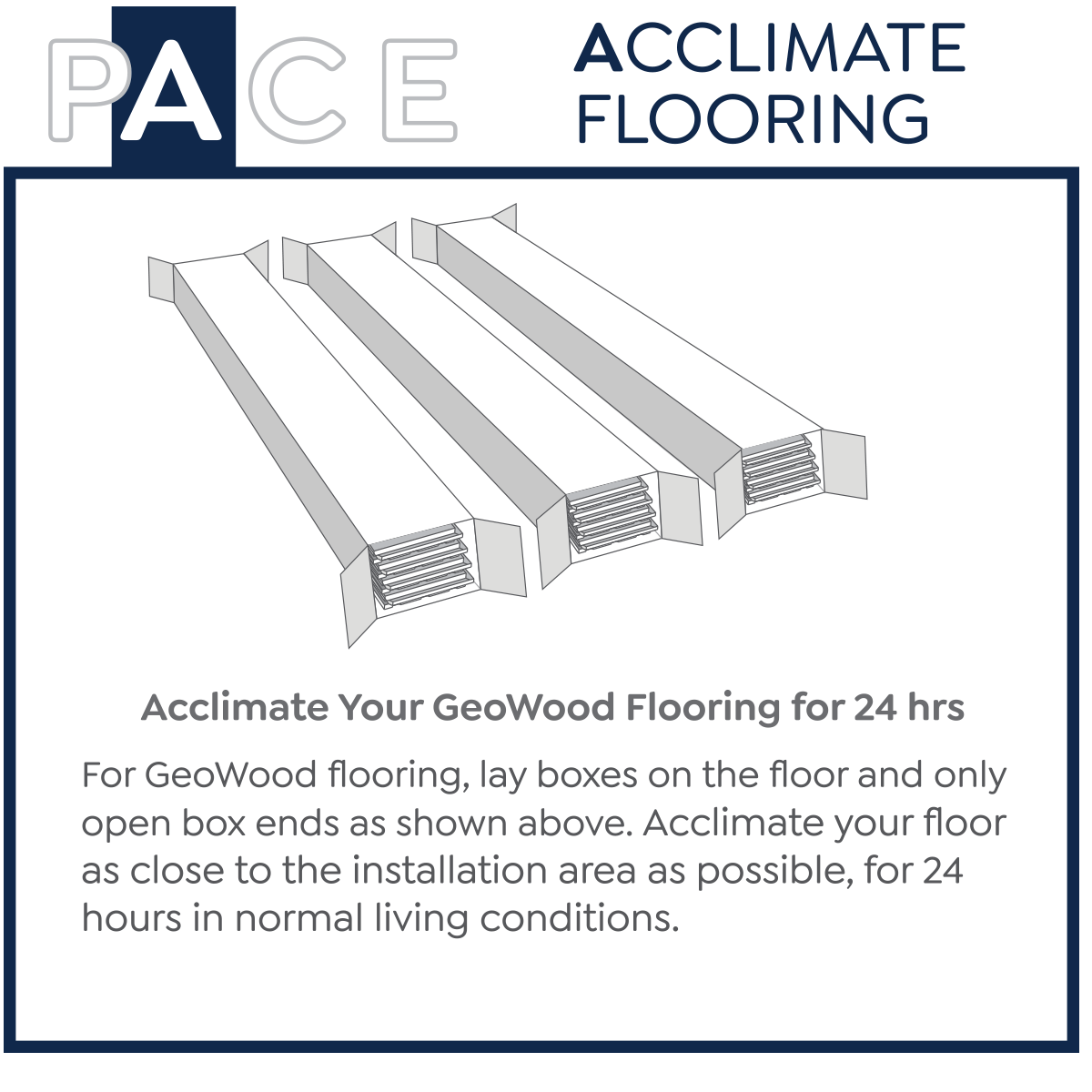

- Due to the nature of CALI GeoWood, typical acclimation is for 24 hours. Flooring does not need to be taken out of the boxes, just opened at the ends.

Pre-Installation Preparation

Prior to installation, inspect planks in daylight for visible faults/damage. Check if subfloor/site conditions comply with the specifications described in these instructions. If you are not satisfied do not install, and contact your supplier. CALI is not responsible for flooring that is installed with visible defects.

Recommended Tools

|

|

Subfloor Requirements

General

- Floating floors can be laid on top of most hard surfaces (e.g. concrete, ceramics, wood)

- Soft subfloors (e.g. carpets) must be removed

- The subfloor must be level – Flat to 3/16” per 10-foot radius

- The subfloor must be clean = Thoroughly swept and free of all debris

- The subfloor must be dry

- The subfloor must be structurally sound

Even though CALI GeoWood Plank Flooring is water resistant it is NOT considered a moisture barrier. Hence, we always require the use of a moisture barrier (like 6mil plastic) on concrete.

Acceptable Subfloor Types

- CD Exposure 1 plywood (grade stamped US PS1-95)

- OSB Exposure 1subfloor panels

- Underlayment grade particleboard

- Concrete slab

- Existing wood flooring (exception – not warrantied if glued over concrete)

- Ceramic tile (must fill in grout lines with a compatible patch compound)

- Resilient tile and sheet vinyl

Acceptable Subfloor Thickness Requirements:

| Joist System Spacing (inches on center) | Minimum Thickness |

| 12” | 5/8” |

| 12” to 16” | 3/4” |

| 16” to 19.2” | 7/8” |

| 19.3” to 24” | 1-1/8” |

Glue Down Details

Wood subfloors must be securely fastened. A best practice is to nail or screw every 6” along joists to avoid squeaking. If leveling is needed, sand down high spots and fill in low spots with a Portland based leveling compound.

Tip: If your plywood, OSB or particle board subfloor is reading higher than 12% MC it is advised to find and correct the source of moisture intrusion before continuing installation. CALI is not responsible for any damage caused by moisture intrusion.

Concrete subfloors must be fully cured and at least 60 days old, preferably 90 days old. If leveling is needed, grind down high spots and level low spots with a Portland based leveling compound.

Tip: When laying 6 mil plastic it is always advised to overlap the seams at least 6” and cover all seams with duct tape.

Slabs on or below grade must be free of hydrostatic pressure.

Important: CALI GeoWood Plank flooring is water resistant, however moisture intrusions from concrete hydrostatic pressure, flooding, or plumbing leaks, along with high levels of alkalinity, can affect the floor over time. Moisture can also be trapped below the flooring and create mold or mildew. The installer, not CALI is responsible for making sure the concrete moisture and alkalinity are suitable prior to installing this floor.

Ceramic Tile, resilient tile and sheet vinyl must be well-bonded to subfloor, in good condition, clean and level. We do not recommend sanding existing vinyl floors, as they may contain asbestos. We do recommend filling any grout lines or embossing with a compatible patch compound. Any damaged caused by skipping this step will not be covered by CALI.

Crawlspaces must have a minimum of a 6-mil polyethylene sheeting covering any exposed earth. Crawl spaces must have adequate ventilation and a minimum of 18” of air space between the ground and the floor joist.

Radiant Heat Systems

CALI GeoWood flooring is only recommended for use over radiant heat systems if the special requirements specified by the National Wood Flooring Association are met (please refer to the NWFA’s Radiant Heat Guidelines). Ensuring stable job site conditions, subfloor suitability and proper acclimation are especially important when installing over a radiant heat system. It is the responsibility of the installer to ensure that the recommended environmental conditions are met for installation. Refer to your radiant heat system manufacturer to determine its compatibility with wood flooring, and to learn the specific requirements for installation.

- Because of the wide variety of systems on the market (Hydronic, embedded in concrete, electrical wire/coil, heating film/mat) each with its own features and applications it is recommended that the user consult with the radiant heating provider for best practices, installation methods and proper subfloors.

- With GeoWood flooring the floating installation method is the only method recommended for use with radiant heat systems.

- Radiant heat system must be turned on and in operation for at least 3 days before installation. The flooring must be acclimated per GeoWood’s flooring acclimation instruction (https://www.CALIbamboo.com/flooringinstallation/) over the radiant heat with the system turned on throughout the acclimation timeframe.

- The system must be turned down to 65°F and maintained 24 hours prior to installation.

- Once install is complete, turn system back on and slowly bring back up to normal operating temperature over a period 4-5 days.

- Floor should never be heated over 85°F. Consult with your radiant heating system manufacturer to successfully limit the maximum temperature. The use of an in-floor temperature sensor is highly recommended.

- Always remember that rugs placed over radiant heated flooring can increase the surface temperature in that area by 3° to 5°F degrees.

- Relative Humidity must be maintained between 35-65%.

- When turning off the radiant heat system it must be turned down slowly at a rate of 1.5° degrees per day. You should never just turn the system off.

- For additional information on radiant heating systems please refer to http://www.radiantpanelassociation.org or the NWFA’s Radiant Heat Guidelines.

Floating Click-Lock Installation of Flooring by CALI

Floating Click-Lock Installation of Flooring by CALI

Before laying: Measure the room at right angle to the direction of the planks. Planks in the final row should be at least 2” in width. Due to this rule, planks in the first row can be cut to smaller size if needed. Shuffle planks in order to obtain a pleasant blend of shades. Lay planks preferably following the direction of the main source of light. We recommend laying on wooden floors crossways to the existing floorboard. You should never nail or screw planks to the subfloor.

- Floor should be installed from several cartons at the same time to ensure good color, shade and appearance.

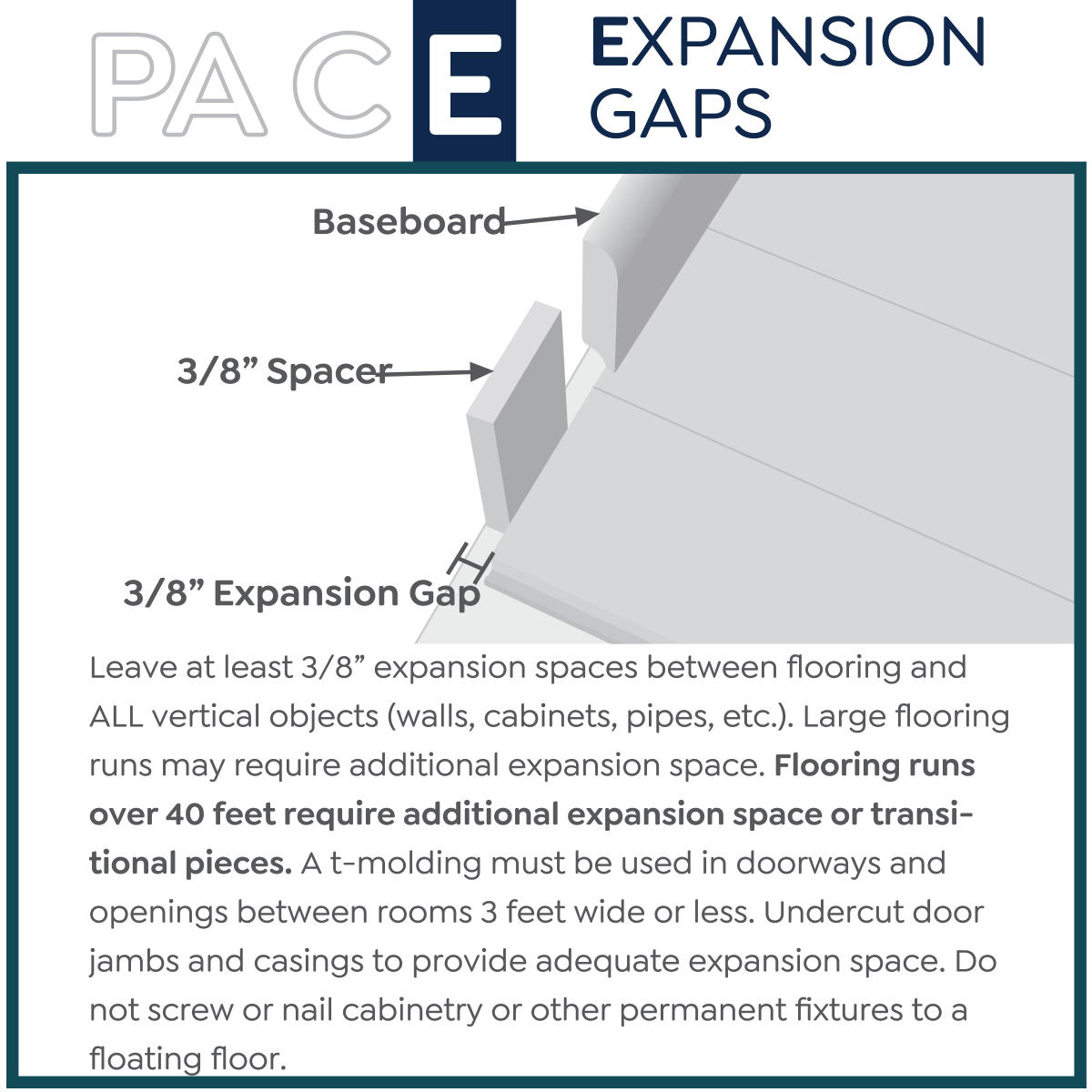

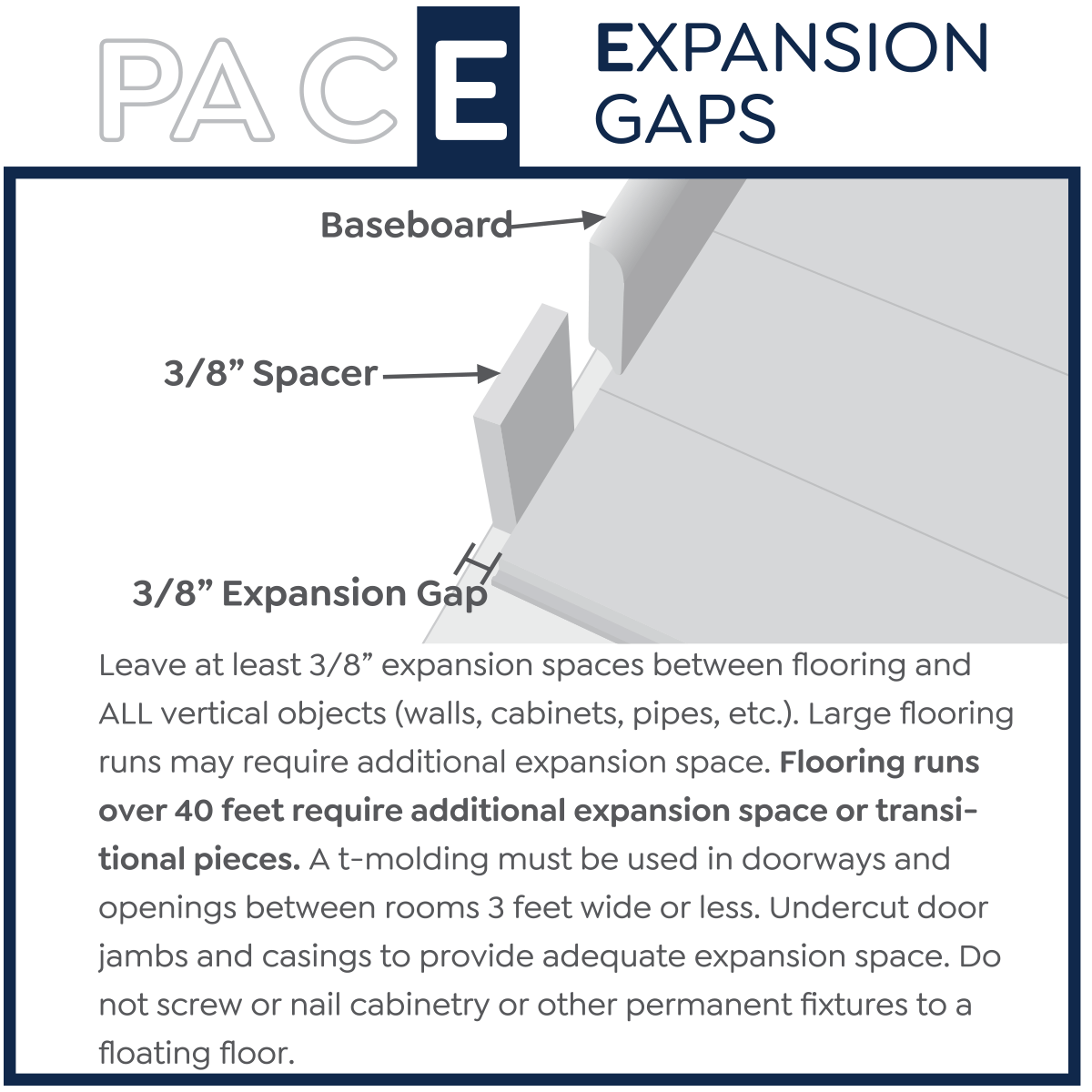

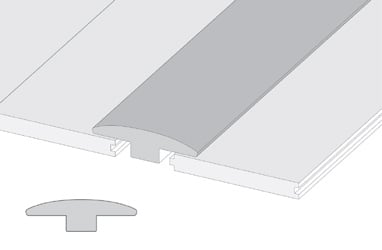

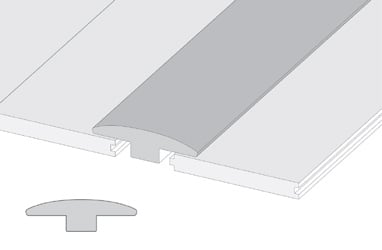

Expansion gaps: Even though CALI GeoWood Planks will have very minimal expansion and contraction it is still required to leave 3/8” expansion space around the perimeter as well as all fixed objects (tile, fireplace, cabinets). A t-molding must be used in doorways and openings between rooms 3 feet wide or less.

- If the installation area exceeds 30 feet, a greater expansion space is required; approximately 1/16” for every additional ten (10) feet. If the floating installation exceeds 40 feet in either direction the use of a transition piece or additional expansion space is necessary.

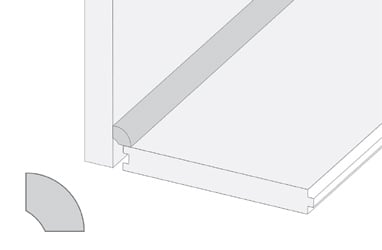

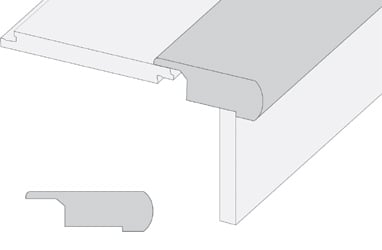

- To cover your expansion space, CALI carries matching wood flooring moldings that include reducers, t moldings, baseboards, quarter rounds, and thresholds. Matching stair parts are also available; including stair nosing, treads and risers. Please visit CALI’s Flooring Accessories webpage. Please note: accessory offerings differ between GeoWood Bamboo and GeoWood Oak.

Tip: When installing around pipes, drill the hole 3/4” larger than the diameter of the pipes.

Installing the First Row:

Step 1

It is recommended to start by installing the first 3 rows at the same time. This will help to minimize any shifting of the product.

Step 2

Start by using a full plank to start the first row, roughly a half plank for the second row and roughly a quarter plank for the third row.

Step 3

The first 3 planks should be installed by angling the plank up slightly, pushing forward and interlocking the side tongue. The long side of the plank should fit snug with no gapping.

Step 4

Once the 3 pieces have been installed continue by installing full planks on each row until you get to the end of each row.

Next Steps:

Step 1

Installing the second plank of the first row requires engaging the butt ends together. Please note the plank is not yet “locked” in place.

Step 2

Install the second plank of the second row. Position the long side of the plank with the tongue side, fully engage into the receiver of the first row of product. Lower the plank to the floor insuring that the end joint is overlapping and perfectly aligned, with firm pressure; push the end joint downward till the end of the plank snaps in place.

Step 3

Continue the installation by repeating step 2. It is important to make sure that the first three rows are straight and square as they can affect the entire installation.

Step 4

Cut the final board in each row to proper length and install. If cut pieces are at least 8 inches in length, they can be used as starter pieces in another row. Caution when doing this make sure to not create a repeating pattern.

Step 5

Once the first three rows have been completed you can continue the install one row at a time.

Installing the Final Row:

Step 1

The last row may need to be cut lengthwise (ripped). Make sure ripped piece is at least 2 inches in width.

Step 2

Place the last row of boards to be fit on top of the last row of installed boards. Use a piece of plank or tile as a scribe to trace the contour of the wall.

Step 3

Mark where the board will be cut. If the fit of the wall is simple and straight, simply measure for the correct fit and cut.

Step 4

After boards are cut, position boards and tap all joints (long AND short ends) with the rubber mallet.

GeoWood Flooring Care & Maintenance Tips

GeoWood Flooring Care & Maintenance Tips

|

WATCH NEXT: Cleaning Care for Vinyl Flooring |

- For Cleaning, we recommend dry or damp mopping as needed using Bona Professional cleaner or similar.

- Do not use anything abrasive or harsh chemicals to clean the floor. Never use any of the following products on your floor: ammonia-based cleaners, mineral spirits, acrylic finishes, wax-based products, detergents, bleach, polishes, oil soap, abrasive cleaning soaps, acidic materials such as vinegar.

- Never apply wax treatments or top coats to the floor.

- Do not drag furniture across the floor, use felt pads on chair and furniture legs.

- Keep pet’s nails trimmed to avoid excess scratching.

- Sweep or vacuum the floor regularly to remove loose dirt. Do NOT use vacuums that use a beater bar or turn beater bar off.

- Place quality walk-off mats at all entrances to retain tracked in dirt, grit and moisture, never use latex or rubber backed mats as they can permanently stain the floor.

- Area rugs are also recommended in front of kitchen sinks and in high traffic areas.

- Although the CALI GeoWood Flooring is water resistant, it is still a best practice to avoid excessive moisture on the floor. Therefore, we recommend soaking up spills immediately using a dry towel or dry mop.

- Limit direct sunlight on floor by using curtains and blinds in areas that are exposed to high UV rays.

- Heating units or non-insulated ductwork close to the flooring or subfloor may cause “hot spots” which must be eliminated prior to installation.

- Heavy furniture (500+ lbs.) may obstruct the free, natural movement of a floated floor. Restricting this movement in certain areas can lead to problems such as buckling or separation when the floor experiences natural expansion and/or contraction.

Glue-Down Pre-Installation

Glue-Down Pre-Installation

Before you begin installation, remember to P.A.C.E. yourself with the checklist below.

Note: Flooring not used for its intended purpose will not be covered under warranty.

- Upon ordering of GeoWood floor materials consider adding an additional 5% to allow for cutting waste and grading allowance.

- CALI flooring is manufactured in accordance with accepted industry standards, which permit manufacturing, grading and natural deficiencies not to exceed 5%. If more than 5% of the material is unusable, do not install the flooring. Immediately contact the distributor/retailer from which the flooring was purchased. No claim will be accepted for materials with visible defects once they are installed. Installation of any material serves as acceptance of the material delivered.

- Installer/Owner assumes all responsibility to inspect all flooring before installation. Planks deemed unacceptable in appearance can be placed in closets, near walls or simply not be used. Pieces with glaring defects that can be seen from a standing position should be cut off or not be used as use constitutes acceptance.

- It is the responsibility of the installer/homeowner to determine if the job site conditions, environmental conditions and sub-floor are acceptable for the installation of CALI GeoWood Plank flooring. Prior to installation, the installer/owner must determine that the jobsite meets or exceeds all applicable National Wood Flooring Association Installation Guidelines. CALI does NOT warrant against failure resulting from or connected with subfloor, job site damage, or environmental deficiencies after installation. CALI makes no warranty or guarantee of the quality of the chosen installer’s work or of a particular installation performed by him or her. CALI disclaims all liability for any errors or improprieties in the installation of its products by an installer.

- Floor noise is normal and will vary from one installation type to the next. Occasional noise is due to structural movement and may relate to sub-floor type, flatness, deflection, and/or related to the fasteners, changes in environmental conditions, relative humidity and the amount of topside pressure applied to the flooring. For these reasons floor noise is not considered a product or manufacturer defect.

- During installation, it is the installer’s responsibility to document all jobsite conditions and measurements including the installation date, site relative humidity, temperature, and subfloor moisture content. This information must be retained by the installer and left with the property owner as a permanent record. For a complete list of points to address prior to installation, refer to the NWFA Jobsite checklist.

- Even when implementing the glue-down method, it is not recommended to install flooring under permanent or fixed cabinetry.

Transport, Storage, Acclimation

- Transport and store cartons in lay down, flat position.

- Stack boxes no more than 8 cartons (4ft) high. Keep away from direct sunlight.

- Room temperature and relative humidity must be consistent with year-round living conditions for at least 5 days prior to installation.

- Due to the nature of CALI GeoWood, typical acclimation is for 24 hours. Flooring does not need to be taken out of the boxes, just opened at the ends.

Pre-Installation Preparation

Prior to installation, inspect planks in daylight for visible faults/damage and color/print. Check if subfloor/site conditions comply with the specifications described in these instructions. If you are not satisfied do not install and contact your supplier. CALI is not responsible for flooring that is installed with visible defects or incorrect color/print.

Recommended Tools

|

|

Subfloor Requirements

General

- General Soft subfloors (e.g. carpets) must be removed

- The subfloor must be level – Flat to 3/16” per 10-foot radius

- The subfloor must be clean = Thoroughly swept and free of all debris

- The subfloor must be dry

- The subfloor must be structurally sound

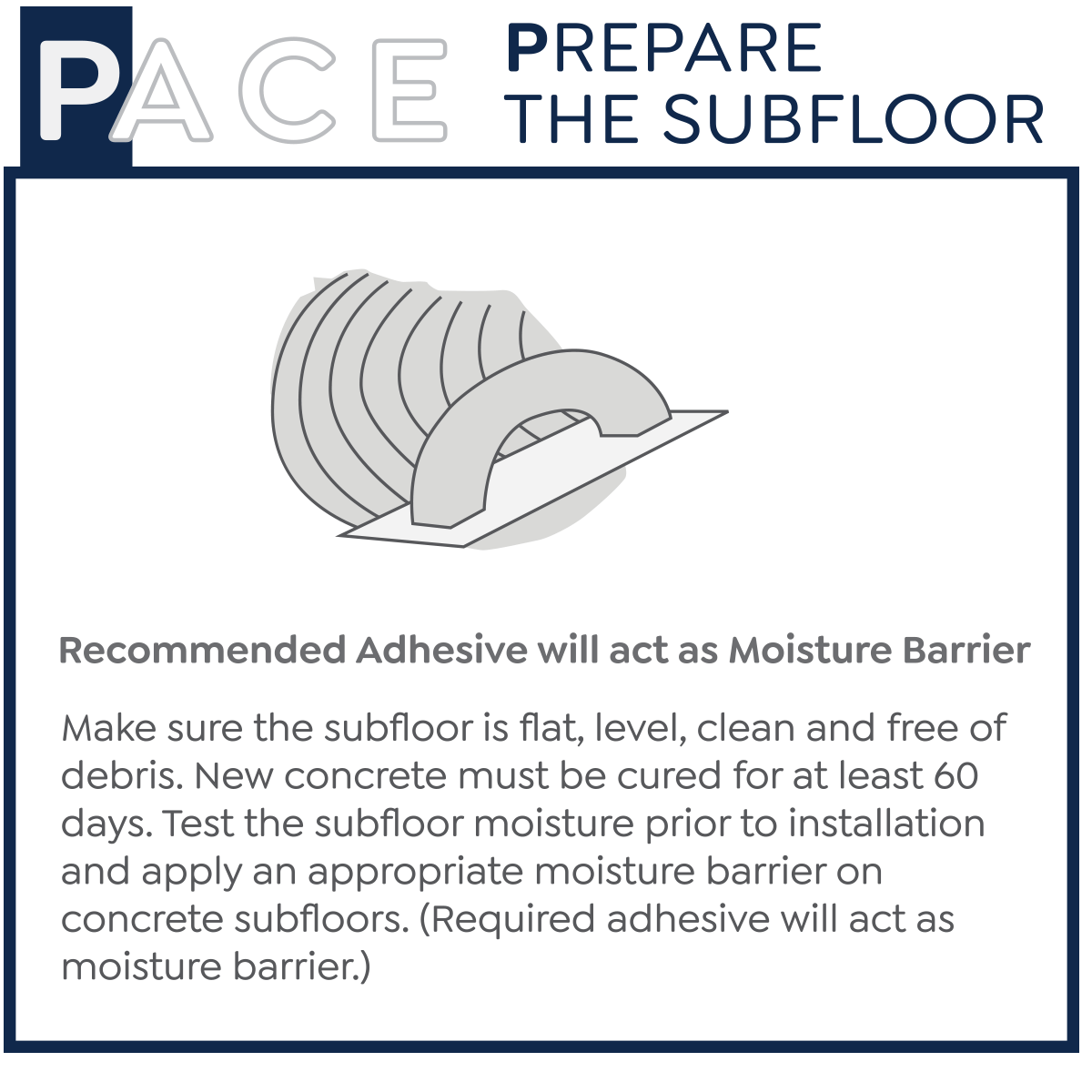

Even though CALI GeoWood Plank Flooring is water resistant it is NOT considered a moisture barrier. Hence, we always require applying a moisture barrier on concrete. When using the glue down method for install the glue will act as your moisture barrier.

Acceptable Subfloor Types

- CD Exposure 1 plywood (grade stamped US PS1-95)

- OSB Exposure 1subfloor panels

- Underlayment grade particleboard

- Existing wood (must be sanded to its raw state)

- Concrete

- Light weight concrete (may require a primer – see Titebond manufacturer for details)

- Ceramic tile (check with Titebond manufacture to see what prep will be needed: patch, self-lever, primer, etc.)

Acceptable Subfloor Thickness Requirements:

| Joist System Spacing (inches on center) | Minimum Thickness |

| 12” | 5/8” |

| 12” to 16” | 3/4” |

| 16” to 19.2” | 7/8” |

| 19.3” to 24” | 1-1/8” |

CALI highly recommends the use of Titebond 670 when gluing CALI GeoWood. The use of any other adhesive is at the discretion of the person or company performing the installation. If you choose to use another adhesive it is highly recommended to use an acrylic based LVT adhesive.

Make sure to follow all Titebond guidelines which include but are not limited to:

- Plywood/OSB/Particle board subfloor moisture must not be over 12%

- Concrete Moisture should not read over 8lbs when using a Calcium Chloride test or 90% RH when using an in-situ probe or Lignomat SDM

- Concrete alkaline levels should not be more than 9.0 pH

- Use a 1/16” Square notch trowel

- For more details please see Titebond 670 product page below: http://www.titebond.com/product.aspx?id=c4128646-56d5-405d-8e6f-3333eccf6d1b

Wood subfloors must be securely fastened. A best practice is to nail or screw every 6” along joists to avoid squeaking. If leveling is needed, sand down high spots and fill in low spots with a Portland based leveling compound.

Tip: If your plywood, OSB or particle board subfloor is reading higher than 12% MC it is advised to find and correct the source of moisture intrusion before continuing installation. CALI is not responsible for any damage caused by moisture intrusion.

Concrete subfloors must be fully cured and at least 60 days old, preferably 90 days old. If leveling is needed, grind down high spots and level low spots with a Portland based leveling compound. Slabs on or below grade must be free of hydrostatic pressure.

Important: CALI GeoWood Plank flooring is water resistant, however moisture intrusions from concrete hydrostatic pressure, flooding, or plumbing leaks, along with high levels of alkalinity, can affect the floor over time. Moisture can also be trapped below the flooring and create mold or mildew. The installer, not CALI is responsible for making sure the concrete moisture and relative humidity are suitable prior to installing this floor.

Crawlspaces must have a minimum of a 6-mil polyethylene sheeting covering any exposed earth. Crawl spaces must have adequate ventilation and a minimum of 18” of air space between the ground and the floor joist.

Radiant Heat Systems

CALI GeoWood flooring is not recommended for use with radiant heat systems when using the glue down method.

Glue-Down Installation of GeoWood Flooring by CALI

Glue-Down Installation of GeoWood Flooring by CALI

Before laying: Measure the room at right angle to the direction of the planks. Planks in the final row should be at least 2” wide. Due to this rule, planks in the first row can be cut to smaller size. Shuffle planks to obtain a pleasant blend of shades. Lay planks preferably following the direction of the main source of light. We recommend laying on wooden floors crossways to the existing floorboard. You should never nail or screw planks to the subfloor.

- Floor should be installed from several cartons at the same time to ensure good color, shade and appearance.

Expansion gaps: Even though CALI GeoWood Plank will have very minimal expansion and contraction it is still required to leave 3/8” expansion space around the perimeter as well as all fixed objects (tile, fireplace, cabinets). A t-molding must be used in doorways and openings between rooms 3 feet wide or less.

- When installing using the glue down method the use of transition pieces becomes optional.

- To cover your expansion space, CALI carries matching wood flooring moldings that include reducers, t moldings, baseboards, quarter rounds, and thresholds. Matching stair parts are also available; including stair nosing, treads and risers. Please visit CALI’s Flooring Accessories webpage. Please note: accessory offerings differ between GeoWood Bamboo and GeoWood Oak.

Tip: When installing around pipes, drill the hole 3/4” larger than the diameter of the pipes.

Installing the First Row:

Step 1

Start out by pouring adhesive on to the subfloor. Make sure you do not pour out too much at one time. CALI does not recommend spreading more than an arm’s length (6 to 8 feet) worth of adhesive at a time. This will help to ensure the glue does not flash over before you can adhere the planks.

Step 2

Use tapping block as necessary to fit planks together but be careful not to let installed floor move on the wet adhesive while you are working. Repeat these steps as you move along with the installation.

Step 3

It is recommended to start by installing the first 3 rows at the same time. This will help to minimize any shifting of the product.

Step 4

Start by using a full plank to start the first row, roughly a half plank for the second row and roughly a quarter plank for the third row.

Step 5

Once the 3 pieces have been installed continue by installing full planks on each row until you get to the end of each row.

Step 6

The first 3 planks should be installed by angling the plank up slightly, pushing forward and interlocking the side tongue. The long side of the plank should fit snug with no gapping.

Next Steps:

Step 7

Installing the second plank of the first row requires engaging the butt ends together. Please note the plank is not yet “locked” in place.

Step 8

Install the second plank of the second row. Position the long side of the plank with the tongue side, fully engage into the receiver of the first row of product. Lower the plank to the floor insuring that the end joint is overlapping and perfectly aligned, with firm pressure; push the end joint downward till the end of the plank snaps in place.

Step 9

Continue the installation by repeating step 6. It is important to make sure that the first three rows are straight and square as they can affect the entire installation.

Step 10

Cut the final board in each row to proper length and install. If cut pieces are at least 8 inches in length, they can be used as starter pieces in another row. Caution when doing this make sure to not create a repeating pattern.

Step 11

Once the first three rows have been completed you can continue the install one row at a time.

Installing the Final Row:

Step 12

The last row may need to be cut lengthwise (ripped). Make sure ripped piece is at least 2 inches in width.

Step 13

Place the last row of boards to be fit on top of the last row of installed boards. Use a piece of plank or tile as a scribe to trace the contour of the wall.

Step 14

Mark where the board will be cut. If the fit of the wall is simple and straight, simply measure for the correct fit and cut.

Step 15

After boards are cut, position boards and tap all joints (long AND short ends) with the rubber mallet.

GeoWood Flooring Care & Maintenance Tips

GeoWood Flooring Care & Maintenance Tips

|

WATCH NEXT: Cleaning Care for Vinyl Flooring |

- To clean up dried glue use either Bostik Ultimate Adhesive Remover or Titebond Adhesive Remover cleaning wipes.

- For Cleaning, we recommend dry or damp mopping as needed using Bona Professional cleaner or similar.

- Do not use anything abrasive or harsh chemicals to clean the floor. Never use any of the following products on your floor: ammonia-based cleaners, mineral spirits, acrylic finishes, wax-based products, detergents, bleach, polishes, oil soap, abrasive cleaning soaps, acidic materials such as vinegar.

- Never apply wax treatments or top coats to the floor.

- Do not drag furniture across the floor, use felt pads on chair and furniture legs.

- Keep pet’s nails trimmed to avoid excess scratching.

- Sweep or vacuum the floor regularly to remove loose dirt. Do NOT use vacuums that use a beater bar or turn beater bar off.

- Place quality walk-off mats at all entrances to retain tracked in dirt, grit and moisture, never use latex or rubber backed mats as they can permanently stain the floor.

- Area rugs are also recommended in front of kitchen sinks and in high traffic areas.

- Although the CALI GeoWood Flooring is water resistant, it is still a best practice to avoid excessive moisture on the floor. Therefore, we recommend soaking up spills immediately using a dry towel or dry mop.

- Limit direct sunlight on floor by using curtains and blinds in areas that are exposed to high UV rays.

- Heating units or non-insulated ductwork close to the flooring or subfloor may cause “hot spots” which must be eliminated prior to installation.

GeoWood Collection & Accessories

GeoWood Collection & Accessories

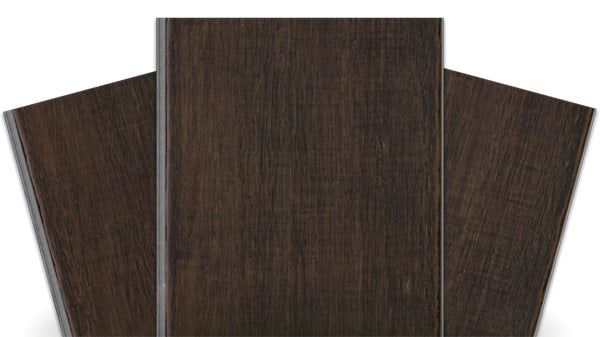

GeoWood Oak Specs & Accessories

Oak Wide Click

7-15/32” Wide

Plank Dims:

74-13/16” L x 7-15/32” W x 11/32” H

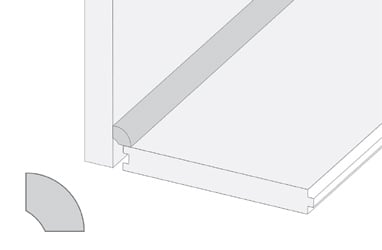

Quarter Round

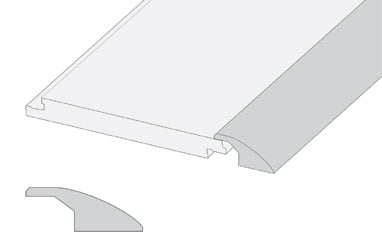

11/32” Overlap Stair Nosing

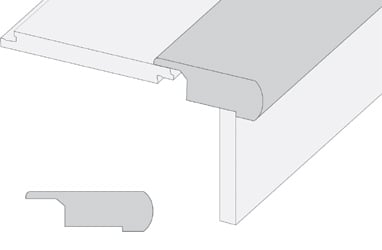

T-Molding

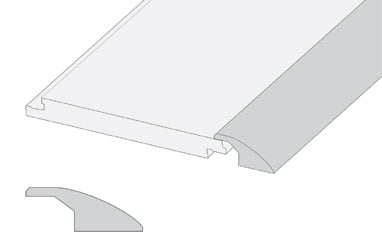

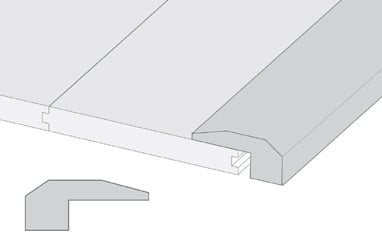

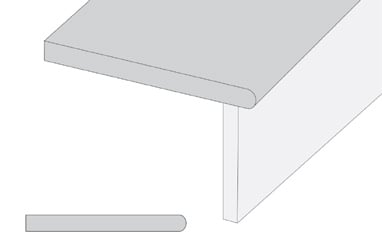

11/32” Overlap Reducer

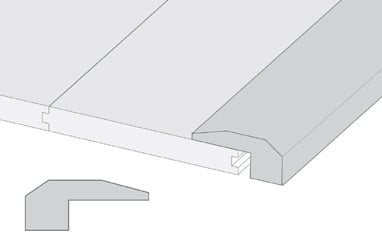

11/32” Threshold

GeoWood Bamboo Specs & Accessories

Bamboo Wide Click

5-19/32” Wide

Plank Dims:

36-1/4” L x 5-19/32” W x 1/4” H

Quarter Round

1/4” Threshold

1/4” Overlap Reducer

1/4” Overlap Stair Nosing

Stair Tread

T-Molding