Solid Eucalyptus Flooring Installation

VIEW OR DOWNLOAD:

Pro Solid Eucalyptus Installation Guide

VIEW OR DOWNLOAD:

Pro Solid Eucalyptus Installation Guide

Pre-Installation

Pre-Installation

Before you begin installation, remember to P.A.C.E. yourself with the checklist below

Prepare Job Site, Acclimation, Control Subfloor Moisture, Environmental Conditions

Proper installation and maintenance are key elements in achieving best flooring results. It is the responsibility of the installer/owner to follow all guidelines provided by CALI for success. Please read through this document completely, additional installation materials such as videos, illustrations and more can also be found at www.CALIfloors.com.

Important Pre-Installation Notes

Note: Flooring not used for its intended purpose will not be covered under warranty.

The following information provided by CALI is intended to serve as a reference guide only. Please carefully read CALI’s installation, maintenance and warranty documentation prior to installation. Follow the National Wood Flooring Association (NWFA) Installation Guidelines when installing your floor.

CALI offers in house technical support as a courtesy to our customers. Consult with one of our flooring experts to find answers to your specific installation questions unique to your application. Contact us by email: [email protected]; or by phone: 1(877) 237-2254 ext. 2.

- Determine the best installation method that suits your application. CALI floors may be Glued or Nailed. Follow the instructions designated for the most suitable installation method for your project.

- Upon ordering of wood floor material consider adding an additional 8% to allow for cutting waste (5%) and grading allowance (3%).

- CALI flooring is manufactured in accordance with accepted industry standards, which permit manufacturing, grading and natural deficiencies not to exceed 5%. If more than 5% of the material is unusable, do not install the flooring. Immediately contact the distributor/retailer from which the flooring was purchased. No claim will be accepted for materials with visible defects once they are installed. Installation of any material serves as acceptance of the material delivered.

- Installer/Owner assumes all responsibility to inspect all flooring before installation. Boards deemed unacceptable in appearance can be placed in closets, near walls or simply not be used. Pieces with glaring defects that can be seen from a standing position should be cut off or not be used as use constitutes acceptance. The use of putty, filler sticks or markers to touch-up flooring during installation is considered normal practice.

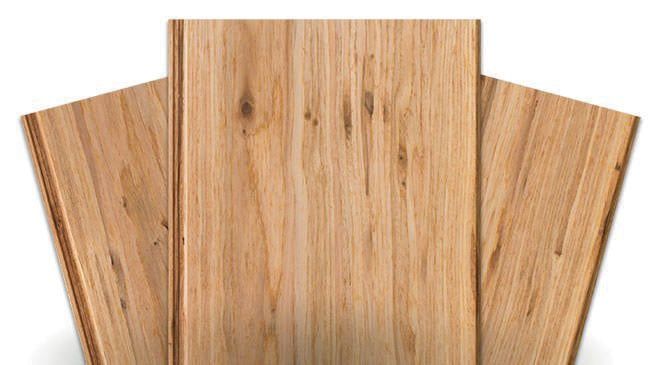

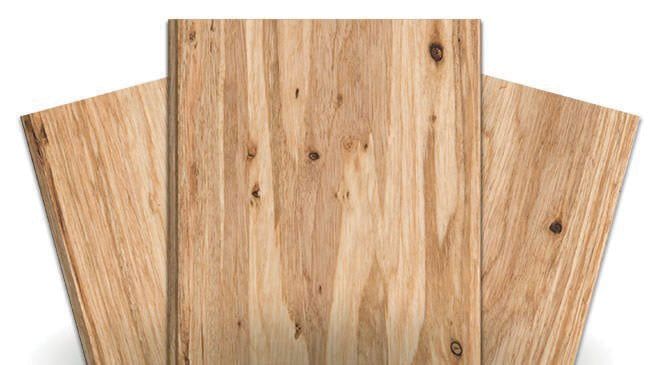

- Because bamboo and eucalyptus are natural products, natural variations in color may occur within and between individual flooring

planks. To visualize the range of colors within the flooring style you are considering, compare your samples to the photos on our web site. During installation, work from several cartons at a time to achieve a uniform appearance across the entire floor. Mix and mingle planks when dry laying the floor for maximum aesthetic appearance. Blend moldings to planks that have similar color. Natural variations in color are not covered under warranty.

planks. To visualize the range of colors within the flooring style you are considering, compare your samples to the photos on our web site. During installation, work from several cartons at a time to achieve a uniform appearance across the entire floor. Mix and mingle planks when dry laying the floor for maximum aesthetic appearance. Blend moldings to planks that have similar color. Natural variations in color are not covered under warranty. - It is the responsibility of the installer/homeowner to determine if the job site conditions, environmental conditions and sub-floor are acceptable for the installation of CALI flooring. Prior to installation, the installer/owner must determine that the jobsite meets or exceeds all applicable National Wood Flooring Association’s Installation Guidelines. CALI does NOT warrant against failure resulting from or connected with subfloor, job site damage, or environmental deficiencies after installation.

- CALI makes no warranty or guarantee of the quality of the chosen installer’s work or of a particular installation performed by him or her. CALI disclaims all liability for any errors or improprieties in the installation of its products by an installer. Please contact the National Wood Flooring Association (800-422-4556) to find a certified installer in your area, or for more information on installation.

- Controlling flooring moisture content is important for success. Bamboo and eucalyptus, like all hardwood flooring species, is hygroscopic; its size and shape changes naturally with the absorption or release of moisture. The amount of movement varies depending on the preventative steps taken at the time of installation (i.e. acclimation, moisture barrier application, etc.) and the stability home environment thereafter. Care should be taken to control fluctuating levels of moisture indoors.

- Floor noise is normal and will vary from one installation type to the next. Occasional noise is due to structural movement and may relate to sub-floor type, flatness, deflection, and/or related to the fasteners, changes in environmental conditions, relative humidity and the amount of topside pressure applied to the flooring. For these reasons floor noise is not considered a product or manufacturer defect.

- CALI is intended for installation on or above grade only. Flooring installed below grade is not covered under warranty

Prior to Installation of CALI Flooring

Job Site Preparation

Prior to installation, it is the installer’s responsibility to determine that the jobsite, environment and subfloor conditions all meet the requirements of the National Wood Flooring Association. Do not deliver flooring to jobsite until the building has been enclosed with windows and doors, all cement, plastering, and other “wet” work has been completed, and a consistent room temperature has been reached. Confirm proper drainage exists around the structure. Lack of moisture protection can allow excessive water or moisture to penetrate basement walls, flow beneath concrete slabs, basement floors, and into crawl spaces. In crawl spaces, exposed earth must be fully covered with minimum 6-mil polyethylene sheeting. Crawl space vents must be open. A moisture retardant such as 6 mil polyethylene film must be placed in crawl spaces. Heating units or non-insulated ductwork close to the flooring or subfloor may cause “hot spots” which must be eliminated prior to installation.

During installation, it is the installer’s responsibility to document all jobsite conditions and measurements including the installation date, flooring moisture content, site relative humidity, temperature, and subfloor moisture content. This information must be retained by the installer and left with the property owner as a permanent record. For a complete list of points to address prior to installation, refer to the NWFA’s Jobsite Checklist.

Subfloor Requirements

General: Subfloor must be structurally sound and meet all NWFA guidelines. All subfloors must be flat to a tolerance of 3/16” in a 10’ radius. Use appropriate leveling products for correcting subfloor deficiencies. Subfloor surfaces must be smooth, clean, dry and free of contaminants that would interfere with an adhesive bond. All subfloors should be tested for moisture content (see “Subfloor Moisture Testing”). If high moisture readings are found, identify the moisture source and correct the problem before installation. Do not install flooring directly over floor joist without proper subflooring.

Appropriate Wood Subfloors Materials

- CD Exposure 1 plywood (grade stamped US PS1-95)

- OSB Exposure 1subfloor panels (grade stamped US PS1-95)

- Solid-board subflooring should be ¾” x 5½” (1” x 6” nominal), Group 1 dense softwoods, No. 2 Common, kiln dried

Acceptable Subfloor Thickness Requirements

| Joist System Spacing (inches on center) | Minimum Thickness |

| 12” | 5/8” |

| 12” to 16” | 3/4” |

| 16” to 19.2” | 7/8” |

| 19.3” to 24” | 1-1/8” |

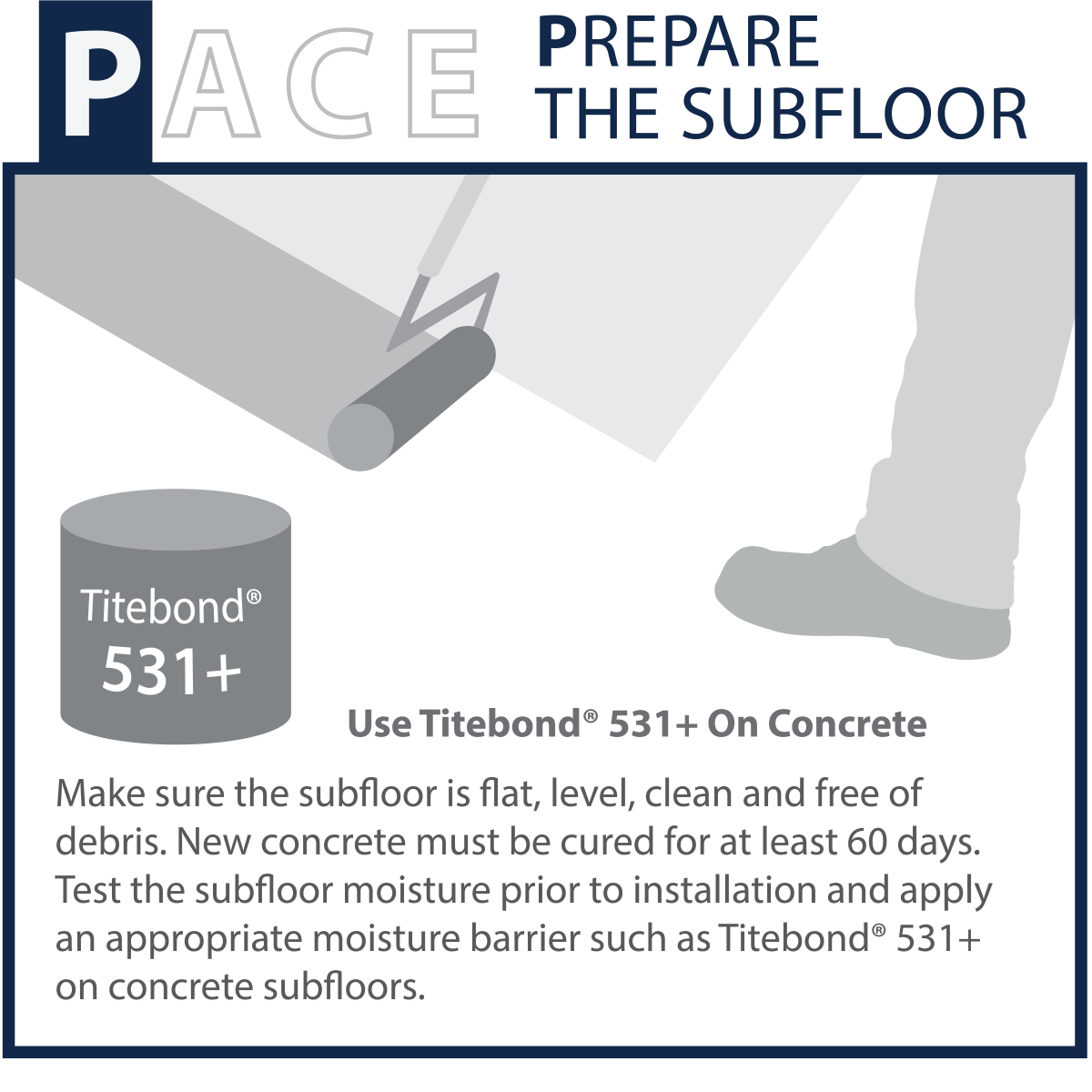

Concrete Subfloors: Subfloor must meet all above requirements. Concrete must be fully cured and at least 60 days old. Concrete must be free of dirt, oil, paint, old adhesive, wax, sealers and curing agents. Concrete that is not properly leveled can cause improper adhesive transfer, hollow spots, and squeaks. Sand or grind down high spots. Level low spots with appropriate leveling material; allow extra drying time for the leveling compounds. Test subfloor moisture content. To minimize moisture transfer from the slab, apply: Titebond 531+ Moisture Control System.

Moisture Testing Subfloor

General: Test the subfloor for moisture content before installation. If high moisture readings are found, identify the moisture source and correct the problem. Extend acclimation time and increase ventilation until the proper conditions have been met. Apply a moisture barrier. Please note that test results are only applicable the day of testing and will not ensure that moisture will not fluctuate with seasonal changes. Regardless of subfloor moisture content, the use of a moisture barrier is required for all installations. CALI does not warrant against moisture related problems. If results show moisture vapor at or exceeding 12%, determine its source and correct problem before installation.

Wood Subfloors: Wood Subfloors: Use moisture meter to test wood subfloor moisture content. If results show moisture vapor at or exceeding 12%, determine its source and correct problem. Do not install the floor without a vapor barrier. CALI always recommends using a moisture/vapor barrier, especially if the moisture content of the flooring and subfloor vary greater than 3%.

Concrete Subfloors: Concrete subfloors must be tested for moisture vapor pressure in more than one place for consistent readings. If test results show moisture vapor exceeds the minimum requirements below, do not install the floor without an impermeable vapor retarder with a perm rating of less than .13 designed to permanently block this moisture.

- Calcium Chloride Test (ASTM F 1869): Maximum vapor emissions cannot exceed 3lbs/1000SF in 24 hours

- Tramex Concrete Moisture Encounter: Moisture readings should not exceed 4% on upper scale

- In-Situ Probe Method (ASTM F 2170): Relative Humidity levels should not exceed 75%

Bamboo Moisture Reading Conversions Also Apply To Eucalyptus Flooring

Delmhorst Moisture Meter Conversion Table

for Strand-Woven Bamboo Flooring

| Meter Reading (Doug. Fir Setting) |

Actual % Moisture Content |

| 6 | 3 |

| 7 | 3.5 |

| 8 | 4 |

| 9 | 4.5 |

| 10 | 5 |

| 11 | 6 |

| 12 | 6.5 |

| 13 | 7 |

| 14 | 7.5 |

| 15 | 8 |

| 16 | 8.5 |

| 17 | 9 |

| 18 | 9.5 |

| 19 | 10 |

| 20 | 11 |

| 21 | 11.5 |

| 22 | 12 |

| 23 | 12.5 |

| 24 | 13 |

| 25 | 13.5 |

| 26 | 14 |

| 27 | 14.5 |

| 28 | 15.5 |

Moisture Testing Bamboo and Eucalyptus Floors

Use a reliable moisture meter that is acceptable for strand bamboo and strand eucalyptus flooring. Examples of acceptable moisture meters include Delmhorst or a Lignomat SDM. Contact the meter manufacture to verify settings for strand bamboo/eucalyptus. Please note that some meters require the use of a substitute setting for bamboo (or eucalyptus), and thus must have the moisture content readings converted in order to get an accurate measurement (such as Delmhorst; see table; right*).

Moisture Barrier Requirements

General: Unexpected changes to subfloor moisture content may cause dimensional changes to the floor. To ensure a lifetime of satisfaction, it is strongly recommended that CALI flooring be installed over a moisture barrier or vapor retarder (following manufactures guidelines) per the following specifications:

Wood Subfloors: For best results, use a moisture barrier/vapor retarder with a perm rating between 0.7 and 50 when tested in accordance with ASTM E-96 Method A. Install as recommended by the manufacturer. Examples of acceptable moisture barriers for wood subfloors include: Silicon Vapor Shield, Asphalt laminated paper (UU-B-790a, Grade B, Type I, Style 1a.) and: Asphalt-saturated kraft paper.

Concrete Subfloors: For concrete applications, a moisture barrier/vapor retarder should be chosen based on concrete moisture content. For unlimited moisture protection, CALI recommends the use of Titebond® 531+ Moisture Control System. Install as recommended by the manufacturer.

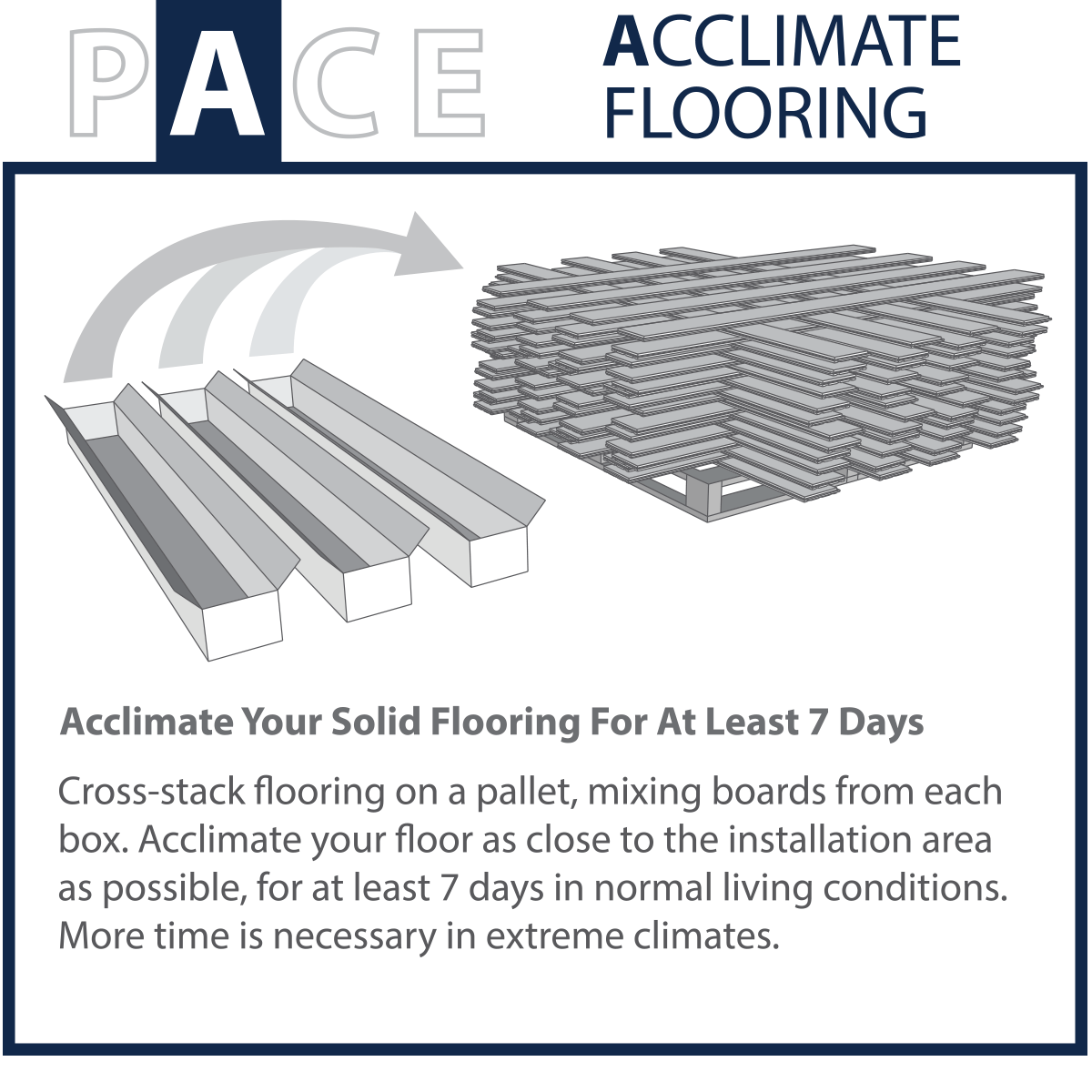

Acclimation & Conditioning of CALI Flooring

The goal of acclimation is to allow the moisture content (MC) of the flooring to fully adjust to its new surroundings before installation.

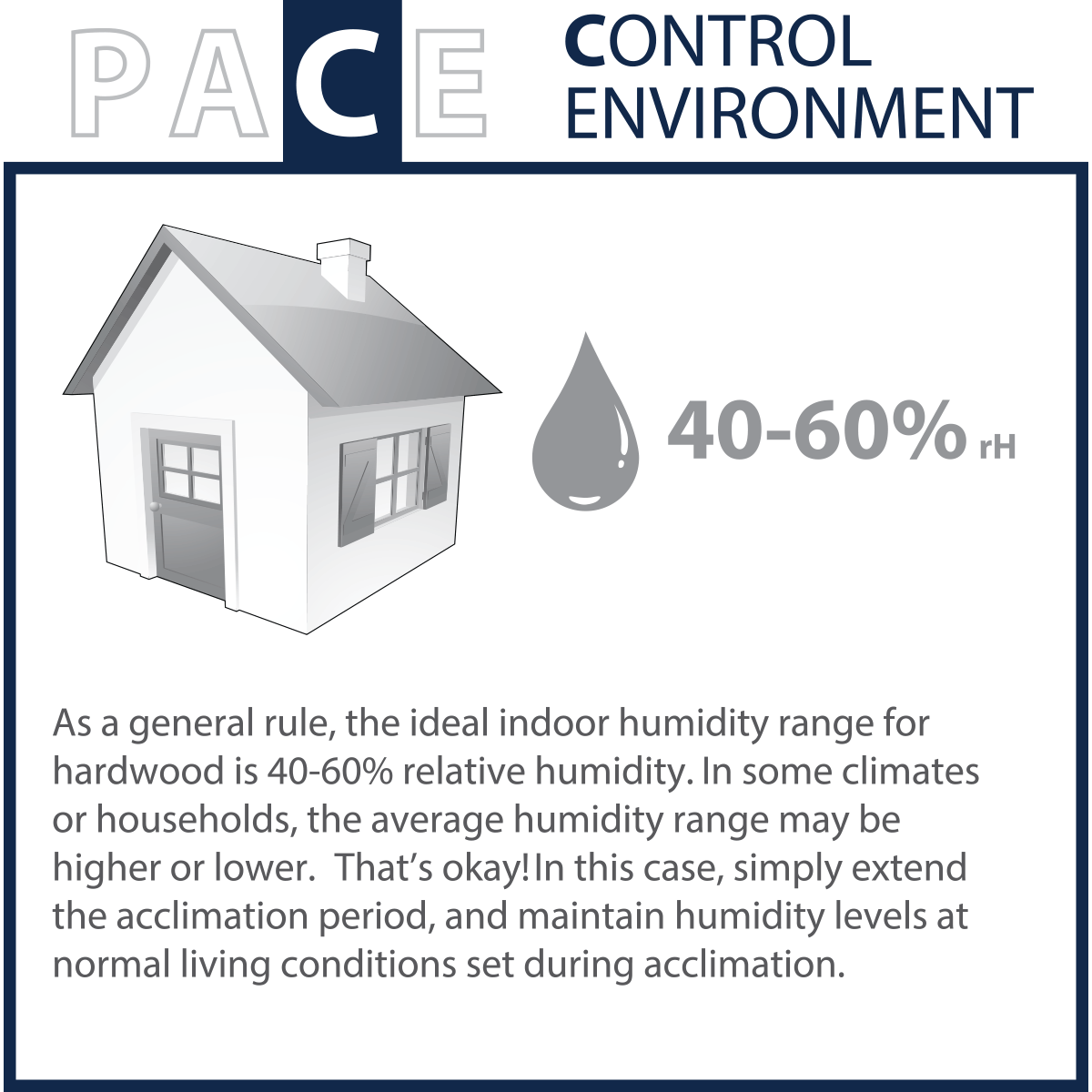

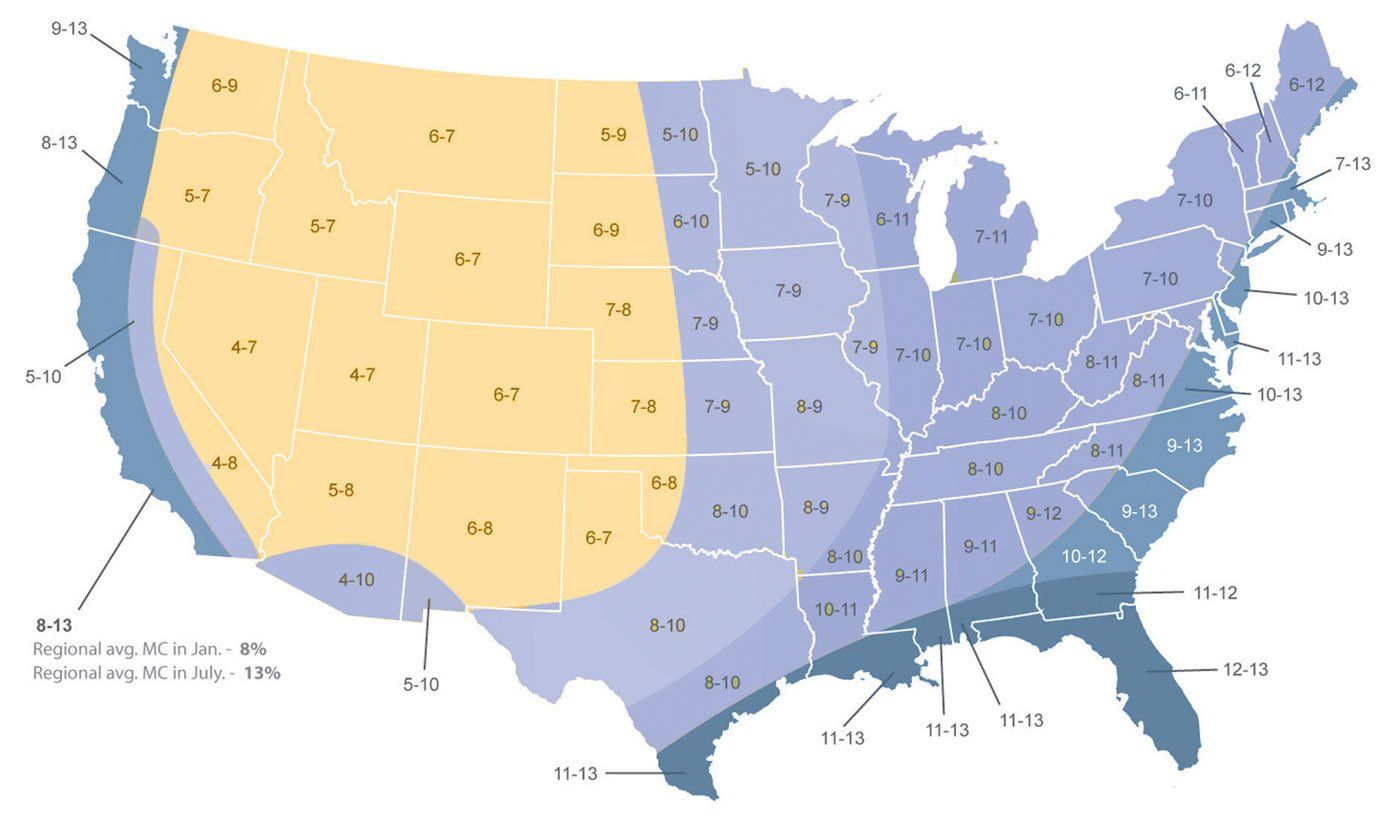

Determine Normal Living Conditions – Ideal interior environmental conditions vary from region to region and job site to job site. It is the installer’s responsibility to know what the “ideal” climate conditions are and customize the acclimation of the floor around those conditions. For a general view of moisture content averages by region, see the map below.

Control Home Conditions Accordingly – Acclimation should occur at normal living conditions. Before opening the cartons, the indoor environment should reflect the room temperature and relative humidity levels expected to be present before, during, and most importantly, after installation. Operate temperature / humidity control systems as normal. Allow normal ventilation through rooms.

Cross-Stacking Flooring Planks – For maximum stability, CALI recommends cross stacking the flooring at the installation site while it acclimates. Remove the flooring from boxes and cross stack planks at least 4” off the subfloor with even spacing between planks to allow for complete and even air-circulation around the flooring.

Acceptable Areas for Acclimation – Acclimate the flooring as close to the center of the installation area as possible. Do not store flooring next to outside walls, in direct sunlight, near air vents or under conditions that don’t reflect the normal home environment. Garages, and exterior patios, for example, are not acceptable areas to store wood flooring during acclimation.

Determine Appropriate Acclimation Time Frame – CALI Engineered flooring should be allowed to acclimate on the job site for 72 hours.

Optimum Flooring Moisture Content (%) by U.S. Region

This map is provided by the NWFA and relates to all hardwood flooring species. For each region, the average equilibrium moisture content (EMC) for hardwood is identified for both January and July. The EMC is the MC (%) that the floor will reach once it has fully acclimated to its environment. This is also the optimum MC for installation, and will provide a general idea of what acclimation measures to take. In each pair of figures, the first number is the average EMC during January; the second is the average EMC during July.

Note: Actual moisture content conditions in any location may differ significantly from these numbers. This map cannot be reliably used as a basis for installation. The most reliable moisture-content numbers can be obtained at the job site. Take moisture content readings of the flooring, subfloor and relative humidity to be sure.

To better understand the specific acclimation requirements for your home, refer to the chart below for correlations between relative humidity (RH), temperature, and flooring moisture content (%). Referencing the weather conditions in your area, find the combination of temperature and RH on the chart. This value represents the flooring moisture content to achieve during acclimation for best results.

Values within chart’s shaded area represent environments with relative humidity (RH) and temperature capable of maintaining the delivered moisture content of 6-10%. These are optimum conditions for maximum flooring stability. For environments outside of this range, allow more time for acclimation. Depending on your local in-home conditions, the use of humidification/dehumidification equipment may be recommended to maintain proper in-home environment.

MOISTURE CONTENT OF WOOD AT VARIOUS TEMPERATURES AND RELATIVE HUMIDITY READINGS

| 30 | 1.4 | 2.6 | 3.7 | 4.6 | 5.5 | 6.3 | 7.1 | 7.9 | 8.7 | 9.5 | 10.4 | 11.3 | 12.4 | 13.5 | 14.9 | 16.5 | 18.5 | 21.0 | 24.3 | 26.0 |

| 40 | 1.4 | 2.6 | 3.7 | 4.6 | 5.5 | 6.3 | 7.1 | 7.9 | 8.7 | 9.5 | 10.4 | 11.3 | 12.4 | 13.5 | 14.9 | 16.5 | 18.5 | 21.0 | 24.3 | 26.0 |

| 50 | 1.4 | 2.6 | 3.7 | 4.6 | 5.5 | 6.3 | 7.1 | 7.9 | 8.7 | 9.5 | 10.4 | 11.3 | 12.4 | 13.5 | 14.9 | 16.5 | 18.5 | 21.0 | 24.3 | 26.0 |

| 60 | 1.3 | 2.5 | 3.6 | 4.6 | 5.4 | 6.2 | 7.0 | 7.8 | 8.6 | 9.4 | 10.2 | 11.1 | 12.1 | 13.3 | 14.6 | 16.2 | 18.2 | 20.7 | 24.1 | 26.8 |

| 70 | 1.3 | 2.5 | 3.5 | 4.5 | 5.4 | 6.2 | 6.0 | 7.7 | 8.5 | 9.2 | 10.1 | 11.0 | 12.0 | 13.1 | 14.4 | 16.0 | 17.9 | 20.5 | 23.9 | 26.6 |

| 80 | 1.3 | 2.4 | 3.5 | 4.4 | 5.3 | 6.1 | 6.8 | 7.6 | 8.3 | 9.1 | 9.9 | 10.8 | 11.7 | 12.0 | 14.2 | 15.7 | 17.7 | 20.2 | 23.6 | 26.3 |

| 90 | 1.2 | 2.3 | 3.4 | 4.3 | 5.1 | 5.9 | 6.7 | 7.4 | 8.1 | 8.9 | 9.7 | 10.5 | 11.5 | 12.6 | 13.9 | 15.4 | 17.3 | 19.8 | 23.3 | 26.0 |

| 100 | 1.2 | 2.3 | 3.3 | 4.2 | 5.0 | 5.8 | 6.5 | 7.2 | 7.9 | 8.7 | 9.5 | 10.3 | 11.2 | 12.3 | 13.6 | 15.1 | 17.0 | 19.5 | 22.9 | 25.6 |

| 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 55 | 60 | 65 | 70 | 75 | 80 | 85 | 90 | 95 | 98 |

Relative Humidity (percent)

Chart taken from Wood Handbook: Wood as an Engineering Material (Agriculture Handbook, 72). Forest Products Laboratory, U.S. Department of Agriculture

Here is an example of how to use the chart above:

- My home is normally and currently maintained at an average temperature of: 70°F

- My home is normally and currently maintained at an average relative humidity of: 40% RH

- The combination of 70°F and 40%RH on the chart shows that the floor should be acclimated moisture content of: 7.7%

- The value of 7.7% MC falls within the shaded area on the chart.

Continue to acclimate the flooring until the flooring moisture content varies less than 3% from the subfloor (e.g. if subfloor has a moisture content of 6%, the maximum moisture content of the flooring should be 9%). Testing of the flooring, subfloor and relative humidity of the job site can determine this (see Subfloor & Flooring Moisture Testing) sections.

Note: Acclimate Engineered Bamboo and Engineered Eucalyptus flooring for a minimum of 48 hours and a maximum of 72 hours. Not properly acclimating wood flooring may cause excessive expansion, shrinkage, dimensional distortion or structural damage. The worst-case scenario is one in which wood flooring is stored outside of the area in which the wood is to be installed. Acclimation is the responsibility of the installer/homeowner

Installation of CALI Flooring

Installation of CALI Flooring

General Guidelines – All Installation Types

- Follow CALI Maintenance & Care Guidelines to keep your floor looking its best after installation.

- Save extra flooring for future repairs.

- Do not install flooring under permanent or fixed cabinetry.

- Floor should be installed from several cartons at the same time to ensure good color, shade and appearance.

- Most installation failures result from jobsite moisture. Do not deliver flooring to the jobsite until problems are corrected.

- CALI flooring is intended for installation on or above grade only. Flooring installed below grade is not covered under warranty.

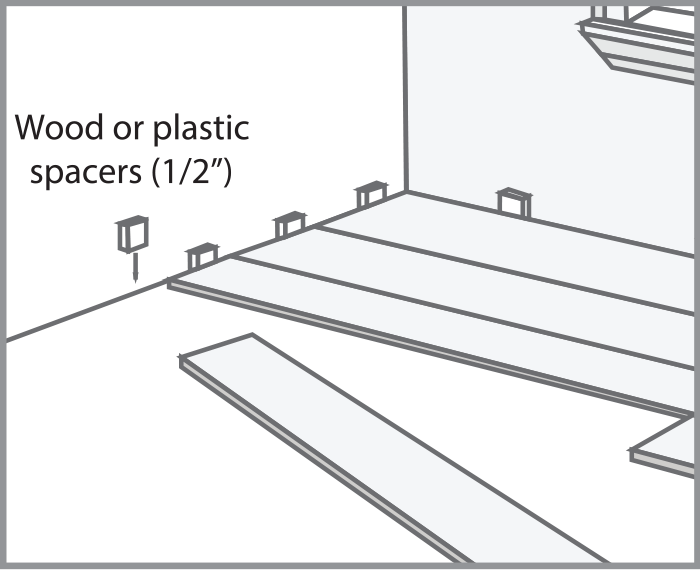

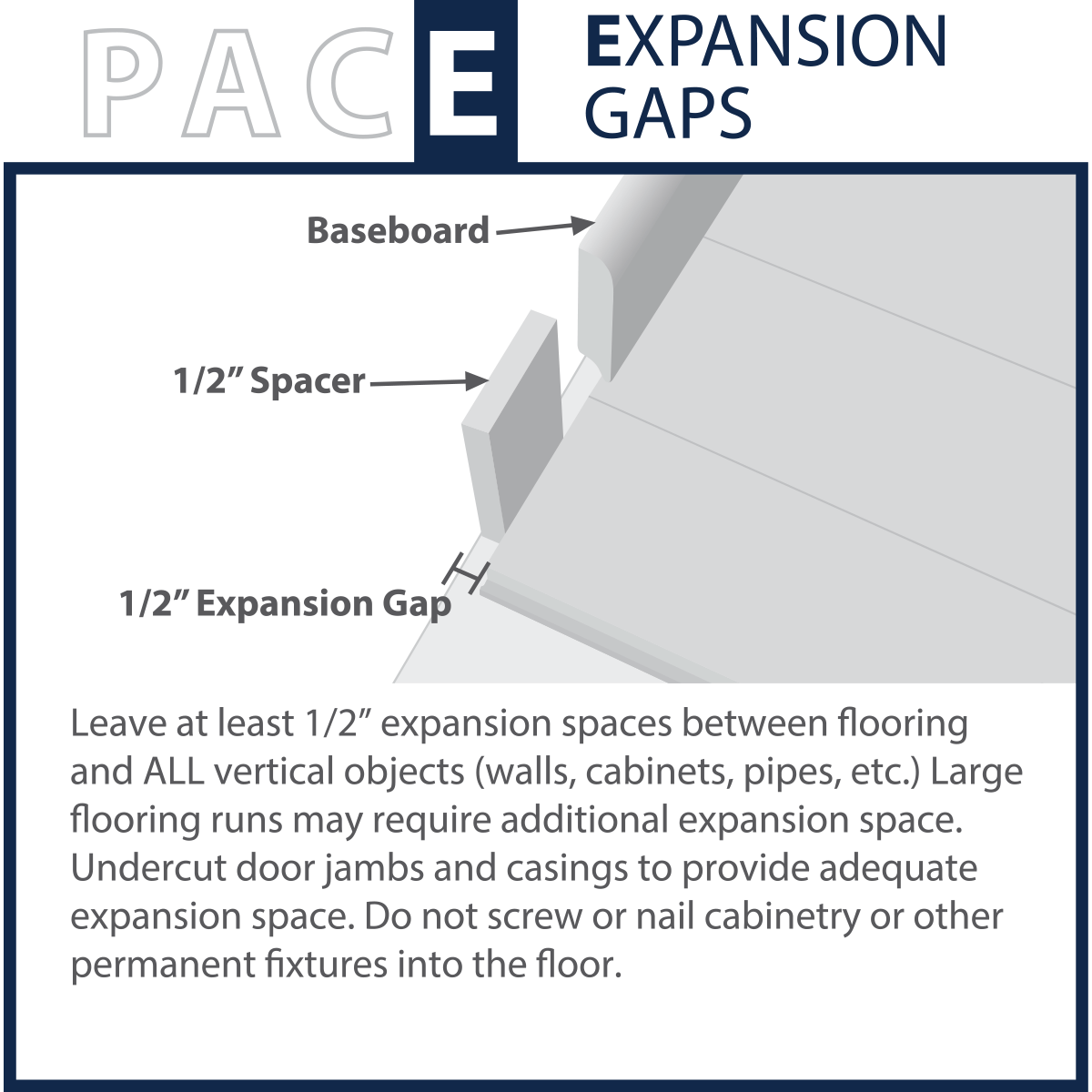

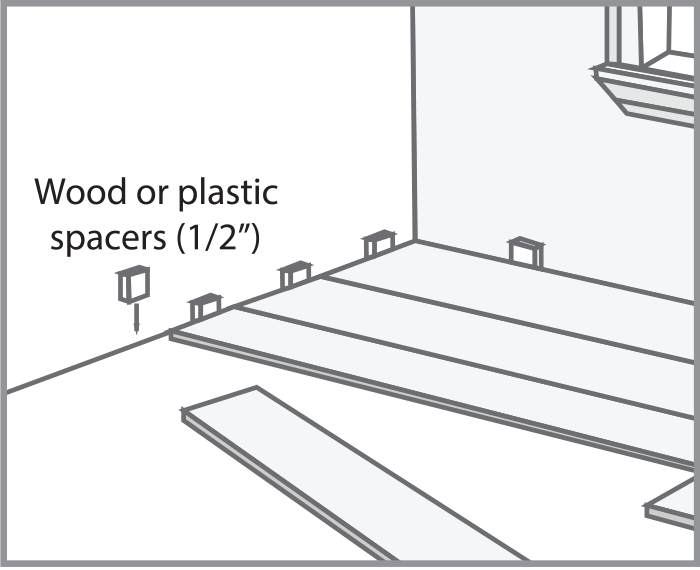

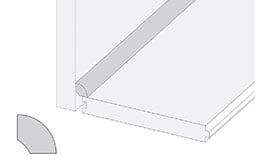

- Since eucalyptus expands with any increase in moisture content, we require leaving at least 1/2” expansion space between flooring and all walls and vertical objects, such as walls, cabinets, pipes, etc.

- 3M blue painter tape #2080 can be used to keep rows or sections of floor boards together until the adhesive has cured. (Incorrect or aggressive tape can harm the finish, do not leave on overnight.)

- During installation, it is the installer’s responsibility to document all jobsite conditions and measurements including the installation date, flooring moisture content, site relative humidity, temperature, and subfloor moisture content. This information must be retained by the installer and left with the property owner as a permanent record.

- Depending on the application, CALI flooring can be installed over an approved underlayment to provide greater thermal insulation and sound isolation qualities. CALI recommends using our Cali Complete™ All-inOne Underlayment, which offers several benefits that include step noise reduction, increased walking comfort, and an industry-leading moisture warranty.

Expansion Space Is Required

- Since eucalyptus expands with any increase in moisture content, we require leaving at least 1/2” expansion space between flooring and all vertical objects (walls, cabinets, pipes, etc.)

- Note that proper expansion space depends not only on the size and flow of the installation, but also on expected seasonal changes in temperature and humidity that may cause the flooring to gain or lose moisture content over time. For example, if an installation takes place when humidity conditions are low, it’s likely that the wood flooring will gain moisture and expand later during humid seasons. In those cases, incorporate additional expansion space through use of spacers or transition moldings.

- Hardwood floors must be able to expand/contract without interference. NEVER install flooring against any vertical or fixed object such as fireplace, columns, islands, door jambs, floor outlets, etc. Failure to follow this guideline may result in tenting, separation or buckled floors. Do not install cabinets or other permanent fixtures on top of the floor.

- To cover your expansion space, CALI carries matching eucalyptus flooring moldings that include reducers, t-moldings, baseboards, quarter rounds, thresholds and vent registers. Matching stair parts are also available; including stair nosing, treads and risers. CALI also provides all the glues and adhesives you will need for to complete your project. Please visit CALI’s Flooring Accessories webpage.

- Undercut door casings and jambs. Remove any existing base, shoe mold or doorway thresholds. These items can be replaced after installation. When undercutting door casings the installer should confirm there is the recommended expansion space. The floor must have 1/16” clearance under the door casing to be able to expand and contract without vertical restriction.

Nail-Down T&G Installation Method

Nail-Down T&G Installation Method

The nail-down method is suitable for wood subfloors using tongue and groove flooring only. Before you start, ensure that the job site, subfloor and environmental conditions are acceptable for installation of CALI engineered flooring. All requirements specified in CALI’s Installation Guidelines must be met. Nailing down a click-lock floor will void the warranty.

Recommended Tools

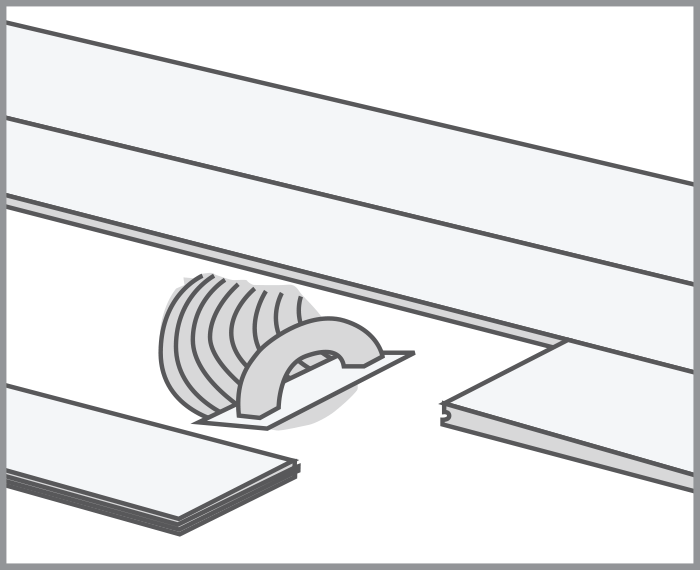

The selection and use of any nailer is at the discretion and responsibility of the installer/ homeowner. Choose a nailer model that is specifically designed for tongue and groove applications. We recommend a Pneumatic 18 Gauge Flooring Nailer (such as the PowerNail 50p flex, 50F, Primatech 550 or similar ). It is the installer’s responsibility to determine the correct pressure for their nailer, and to ensure that the nail is properly seated. Dimpling of the flooring face or edge is not a manufacturing defect.

|

|

|

Nail-Down Installation Steps

Step 1

Use a vapor retarder designed for wood subfloors (see “Moisture Barrier Requirements”).

Step 2

When nailing, the flooring should be always laid perpendicular to the floor joist.

Step 3

Allow at least a 1/2” space for expansion around the perimeter of the room and all vertical objects using spacers. Also see section: “Expansion Space is Required”.

Step 4

Dry lay (do not nail) a few rows before installation to confirm your layout plan.

Step 5

Test the air pressure and angle of your pneumatic nailer with a sample plank to check for correct air pressure before installation. If you note any surface damage (face dimpling), tongue damage (splitting), etc., adjust the air pressure/angle accordingly. Test until dimpling no longer occurs

Step 6

Begin installation next to an outside wall. This is the best reference for establishing a straight working line.

Step 7

Hold starter row in place by blind nailing or gluing to avoid unsightly nail marks.

Step 8

Connect short side of second plank together with the mating side of the first plank.

Step 9

Cut last plank and complete row. Use the remaining plank to start the second row.

Step 10

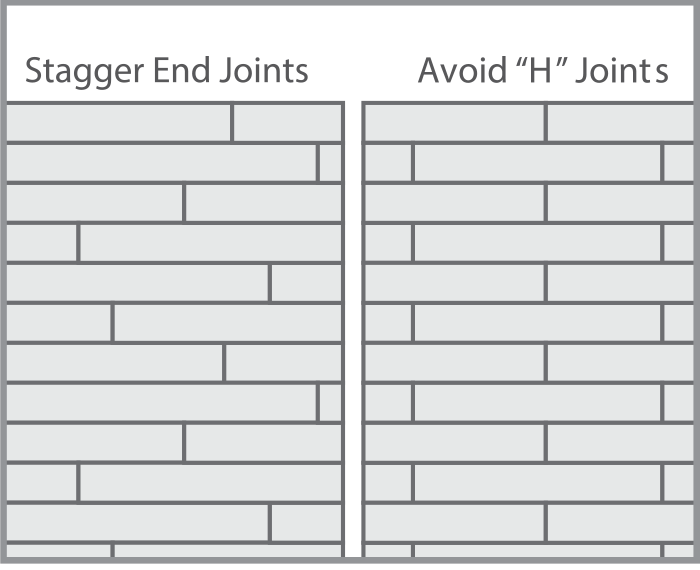

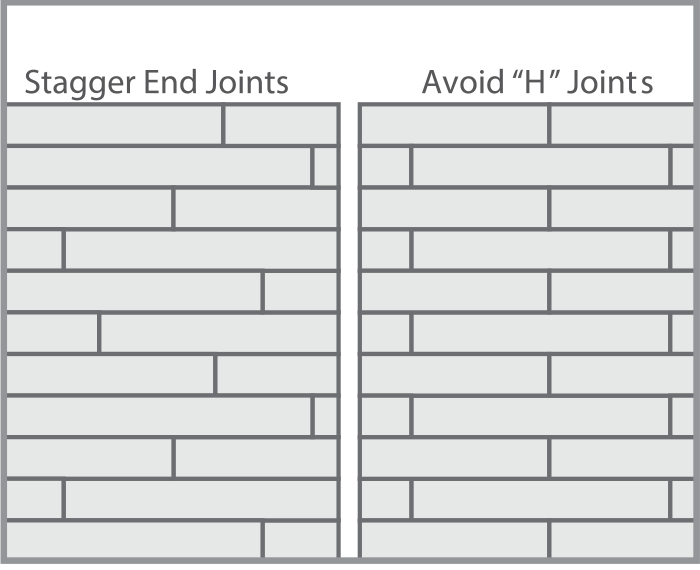

Be sure to offset the end joints of consecutive rows by a minimum of six (6) inches for best appearance.

Step 11

Continue second row by connecting short plank edges first with the long edges.

Step 12

After the first two rows are secured, start the next row by nailing directly above the tongue at a 45 degree angle.

Step 13

Carefully monitor nailer pressure to ensure that the nail head enters the tongue only as deeply as required to allow the adjacent plank to fit properly. Ensure that the nail head rests cleanly in the “pocket”.

Step 14

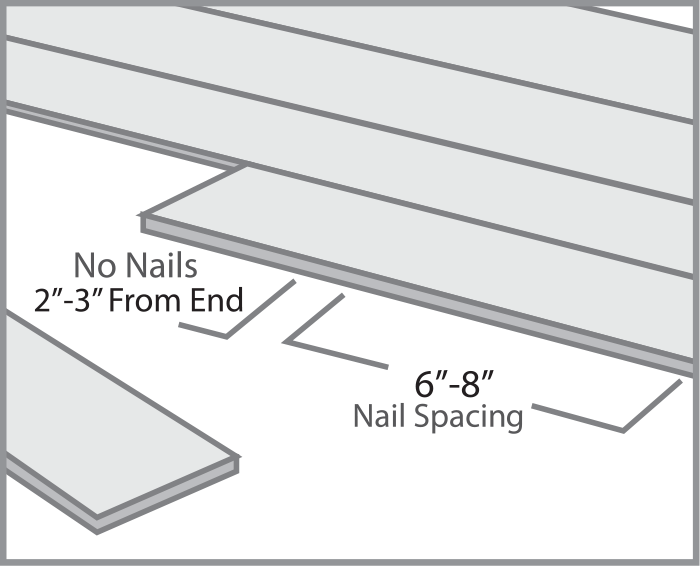

Recommended nail schedule is 6-8 inches along the length of each board. If installing wide+ 7 1/4” the schedule should be tightened to 4-6 inches.

Step 15

Avoid nailing closer than 2-3 inches from the end of the plank.

Step 16

As with the other rows, connect the short edges first and use a pull bar to tap the long edges together.

Step 17

Always check your working lines to be sure the floor is still aligned.

Step 18

The last row may require rip cutting the planks to size.

Step 19

The last two rows will need to be secured in the same manner as the first two.

After Installation

- The newly installed floor is complete and can be walked on immediately.

- Use wood filler or putty to correct minor flooring damage that occurs during installation.

Glue-Down T&G Installation Method

Glue-Down T&G Installation Method

Recommended Adhesive Products

The selection, use and suitability of any adhesive/moisture control system is at the discretion and responsibility of the installer. Always use a moisture barrier and adhesive system manufactured by the same company – never mix products. CALI recommends using Titebond flooring adhesive and moisture barrier systems in accordance with manufactures specifications to receive Titebond’s Platinum installation warranty. Remember: Always Follow Flooring Adhesive Recommendations. CALI does not warrant against adhesive related problems.

Recommended Glue-Down Floor Tools

|

|

Glue-Down Installation Steps

Step 1

Before you start, ensure that the job site, subfloor and environmental conditions are acceptable for installation of CALI engineered flooring. All requirements specified in CALI’s Installation Guidelines must be met.

Step 2

Seal concrete subfloor with appropriate moisture control system prior to installation. CALI recommends Titebond® 531+ Moisture Control System.

Step 3

Allow at least a 1/2” space for expansion around the perimeter of the room and all vertical objects using spacers. Also see section: “Expansion Space is Required”.

Step 4

Dry-lay a couple rows before starting installation to confirm your layout plan.

Step 5

Begin installation next to an outside wall. This is the best reference for establishing a straight working line.

Step 6

Lay the first row of flooring with groove facing the wall. Starter rows should be secured by blind nailing and gluing.

Step 7

Connect short side of second plank together with mating side of the first plank.

Step 8

Cut last plank and complete row. Use the remaining plank to start second row.

Step 9

Offset end joints of consecutive rows by a minimum of 6” for best appearance.

Step 10

With the first row in place, trowel out some adhesive and lay second row by connecting short edges of planks first. Use a pull bar to tap long edges together.

Step 11

Always check your working lines to be sure the floor is still aligned.

Step 12

Use tapping block to fit planks together, but be careful not to let installed floor move on the wet adhesive while you are working.

Step 13

The last row may require rip cutting the planks to size.

Step 14

Flooring planks on perimeter of room may require weight on them until adhesive cures enough to hold them down.

After Installation

- Always remove any adhesive from the surface of the flooring (smudges, fingerprints, etc.) before it dries. Use Titebond’s Adhesive Remover or Bostik’s™ Ultimate Adhesive Remover Towels to immediately remove any adhesive on flooring surface as you go.

- Allow the newly installed floor to fully cure based on adhesive recommendations before walking or moving furniture onto the floor.

Solid Eucalyptus Collection & Accessories

Solid Eucalyptus Collection & Accessories

Flooring System

Wide Click

5-1/4” Wide

Plank Dims:

47-1/4” L x 5-1/4” W x 9/16” H

Wide T&G

5-1/8” Wide

Plank Dims:

48” L x 5-1/8” W x 9/16” H

Flooring Accessories

Quarter Round

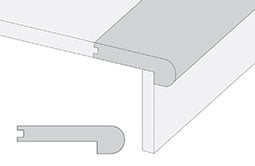

9/16” Stair Nosing

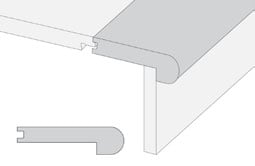

9/16” Click Stair Nosing

9/16” Overlap Stair Nosing

Stair Tread

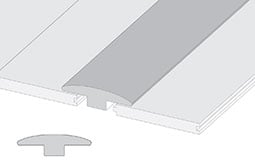

T-Molding

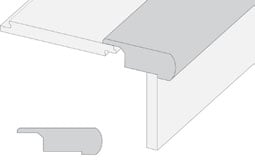

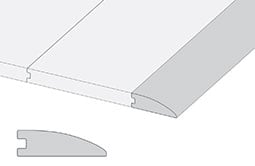

9/16” Reducer

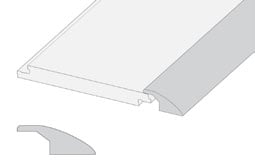

9/16” Overlap Reducer

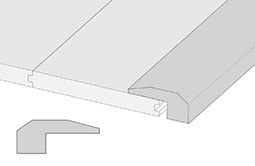

9/16” Threshold